Most teams are trying to “optimize” workflows they have never actually seen end-to-end.

If you asked right now:

Could we draw the actual path a customer ticket, invoice, or onboarding request takes from start to finish, including loops, rework, and delays?

In most organizations, the honest answer is no.

That is not just a vibe problem. It shows up in the data:

- In research commissioned by Celonis, only about 16 percent of businesses say they have complete visibility into their processes, and just 7 percent report complete real-time visibility.

- Deloitte’s global process mining survey found 63 percent of respondents had already started using process mining, and more than 80 percent plan to expand it, because seeing how processes actually run is now a competitive capability.

- A Gartner referenced study projects that roughly 80 percent of organizations will integrate process mining into at least 10 percent of their operations by 2025.

Visibility used to be “nice to have” analysis. It is now table stakes for serious systems & workflow work.

1. The risk of “process blind” optimization

When you do not really see how workflows through systems, everything else becomes guesswork.

Leaders improve the theoretical flowchart, not the reality

- Whiteboard flows show a clean path from A to B.

- Real work bounces between tools, people, and queues.

- Decisions that look quick on paper are actually stuck in inboxes for days.

You end up optimizing the aspiration, not the actual experience.

Automation gets built for the happy path

- RPA, low code, or AI flows are designed around the ideal scenario.

- Exceptions and edge cases (which often make up the bulk of volume) still rely on manual workarounds.

- When the happy path only covers 30 percent of cases, the other 70 percent still hurt customers and staff.

No baseline means no proof of impact

- If you never measured cycle times, touch counts, or rework rates before changing the process, you cannot prove success after.

- People move on to the next initiative without knowing whether the last one worked.

- That fuels the “nothing ever sticks here” story inside the company.

Without visibility, optimization, automation, and AI are all expensive experiments.

2. What process intelligence looks like in practice

Process visibility is not one tool. It is a mix of human insight and hard data.

Collaborative process mapping

- Workshops with the people who actually do the work.

- Mapping current state step by step, including:

- Handoffs

- Approvals

- Rework loops

- “Then I export to Excel and send it to…” moments

- Aligning on where the process really starts and ends.

This gives you the narrative version of reality.

Process mining and event log analysis

- Using logs from systems like CRM, ERP, HRIS, ticketing, and workflow tools.

- Algorithms reconstruct the real paths work takes across systems over time.

- You see:

- Bottlenecks and queues

- Loops, reopens, and rework

- Variant flows by region, product, or team

- You get quantification: how often each path happens, how long it takes, where it stalls.

This gives you the evidence version of reality.

Heat maps of manual touches

- Where are humans forced to intervene most often?

- Where do people copy/paste between systems, chase approvals, or fix bad data?

Those hotspots are usually your highest impact opportunities for simplification, automation, or AI support.

3. A simple visibility first playbook

You do not need to boil the ocean. You need to start with one meaningful journey.

Pick something mission-critical, like:

- Order to cash

- Lead to closed won

- Case to resolution

- Apply to onboard

- Ticket to fulfillment

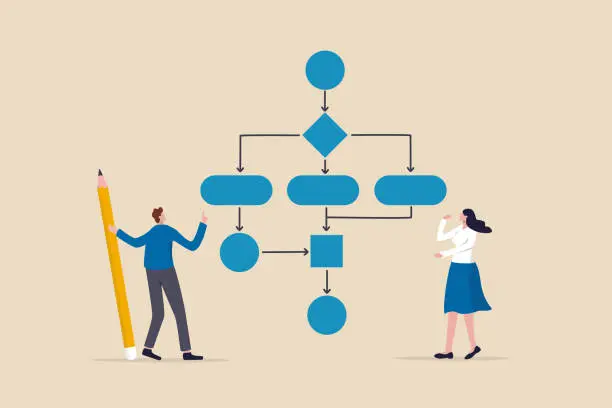

Then run this play:

Step 1: Map the end to end flow with the people doing the work

- Bring representatives from each team that touches the journey.

- Capture every step, handoff, and tool.

- Mark known pain points with simple tags: slow, error prone, confusing, manual.

Step 2: Layer in data from system logs

Where you have system data, use it to validate the map:

- How long does each step actually take on average and at the 90th percentile?

- How often do items bounce back a step?

- How many variants of the process exist by segment or region?

This is where basic process mining or even simple reporting can already expose surprises.

Step 3: Use visibility to prioritize, not guess

- Focus on the steps that combine high volume with high pain.

- Look for “simple” manual touches that occur thousands of times per month.

- Identify where inconsistent paths are breaking experience or control.

From there, you can decide:

- What to simplify (remove steps, rules, or tools)

- What to standardize (less variation where it hurts)

- What to automate or enhance with AI

But only after you know where reality actually is.

4. How Systems & Workflow Optimization should use this

In serious Systems & Workflow Optimization work, visibility is not optional. It is the first gate.

A good advisory partner will:

Make visibility a non-negotiable first step

- Refuse to recommend big tech changes without at least a lightweight current state map.

- Combine interviews, process mapping, and system data to show how work flows now.

Blend process, systems, and data views

- Map not just the human steps, but which systems are touched and how data flows between them.

- Expose where friction lives:

- Duplicate entry

- Conflicting data

- Unsupported exceptions

- Approval dead zones

You are not just optimizing the process. You are optimizing the process + systems combination.

Build a roadmap grounded in evidence, not hunches

- Sequence quick wins (clear bottlenecks, remove obvious waste) ahead of big redesigns or automation.

- Tie each initiative to visible changes in speed, quality, or experience.

- Make it easy to sunset work that is not moving the needle.

The difference is simple: instead of “we think this will help”, you get “we saw this, so we chose this change, and here is the before/after”.

5. One question to open up the visibility conversation

Pick one area of your business where:

- Complaints are constant, or

- Costs and delays are clearly painful, or

- Everyone has strong opinions but no shared facts

Then ask:

Do we have a real, shared view of how this process runs today, end to end, with data?

If the answer is no, the next step is not a new tool, automation, or AI pilot.

It is one focused visibility sprint:

- Map it

- Measure it

- Then change it

That is the foundation every serious Systems & Workflow Optimization effort should be built on.